Reliable Chemical Distribution Across the US

Your trusted distribution partner for high quality ingredients, reliable service, seamless regulatory documentation and complete peace of mind

NAVIGATING DIVERSE SECTORS

Browse by Industries

Home Care and Industrial Cleaning

Flavours and Fragrance

Food and Nutrition

Oil and Gas

Chemical Intermediates

Water Treatment & Mining

C.A.S.E.

Personal Care

Home Care and Industrial Cleaning

Flavours and Fragrance

Food and Nutrition

Oil and Gas

Chemical Intermediates

Water Treatment & Mining

C.A.S.E.

Personal Care

Home Care and Industrial Cleaning

Flavours and Fragrance

Food and Nutrition

Oil and Gas

Chemical Intermediates

Water Treatment & Mining

C.A.S.E.

Personal Care

Premium ingredients for personal care products including emulsifiers, preservatives, and active ingredients for cosmetics and skincare.

Home Care and Industrial Cleaning

Effective cleaning chemicals and surfactants for household and industrial cleaning applications with eco-friendly options.

Flavours and Fragrance

High-quality aroma chemicals and flavor compounds for food, beverage, and fragrance industries with natural and synthetic options.

Food and Nutrition

Food-grade chemicals and additives ensuring safety and quality in food processing, preservation, and nutritional enhancement.

Oil and Gas

Specialized chemicals for oil and gas industry including drilling fluids, corrosion inhibitors, and scale inhibitors for enhanced operations.

Chemical Intermediates

Essential chemical building blocks and intermediates for pharmaceutical, agrochemical, and specialty chemical manufacturing.

Water Treatment & Mining

Leading provider of water treatment and mining solutions with high-quality chemicals for purification, coagulation, and pH adjustment processes.

C.A.S.E.

Comprehensive solutions for Coatings, Adhesives, Sealants, and Elastomers with innovative chemical technologies.

TOP OF THE LINE

Top Products

Caustic Soda Flakes

ELRASATM - CSF

Sodium Laureth Sulphate (SLES)

ELSURFACTM - SES70

Linear Alkylbenzene Sulfonic Acid (LABSA)

ELSURFACTM - LSA

Cocamindo propyl betaine (CAPB)

ELSURFACTM - CAB35

Citric Acid

ELAROMATM - CAmHy

Nonylphenol-9

ELSURFTM - NPE9

Glycerine

ELHUMETM - GLY

Soda Ash

ELRASATM - SAL

Cetostearyl Alcohol

ELVISCTM - CTO55

Hydrochloric Acid

ELRASATM - HCA

Caustic Soda Flakes

ELRASATM - CSF

Sodium Laureth Sulphate (SLES)

ELSURFACTM - SES70

Linear Alkylbenzene Sulfonic Acid (LABSA)

ELSURFACTM - LSA

Cocamindo propyl betaine (CAPB)

ELSURFACTM - CAB35

Citric Acid

ELAROMATM - CAmHy

Nonylphenol-9

ELSURFTM - NPE9

Glycerine

ELHUMETM - GLY

Soda Ash

ELRASATM - SAL

Cetostearyl Alcohol

ELVISCTM - CTO55

Hydrochloric Acid

ELRASATM - HCAVISIONARY STEPS

The Elchemy Advantage

Local Presence

With warehouses in New Jersey, Houston and other key regions, Elchemy is a dependable local partner for high quality chemical ingredients, enabling faster fulfillment and smoother operations.

Support You Can Rely On

Our dedicated support team is available around the clock to help with anything you need. Whether it’s a quick clarification or a detailed request, we are just a call away.

Technology-driven Operations

Our platform offers real-time access to inventory, shipment tracking, and documentation in one place. Empower your teams with full visibility for faster decision-making

Cost Efficiency

Our diverse supplier base and lean operations help us offer competitive pricing while maintaining product quality, regulatory support, and on-time delivery

Regulatory Compliance

We go the extra mile to ensure ingredients are sourced ethically and sustainably. Every product is supported by complete documentation that meets U.S. and global standards, including Kosher, Halal

Quality Commitment

We partner with trusted, globally audited manufacturers. Every product is backed by a Certificate of Analysis, Safety Data Sheet, and traceable supply chain for consistency and safety

Local Presence

With warehouses in New Jersey, Houston and other key regions, Elchemy is a dependable local partner for high quality chemical ingredients, enabling faster fulfillment and smoother operations.

Support You Can Rely On

Our dedicated support team is available around the clock to help with anything you need. Whether it’s a quick clarification or a detailed request, we are just a call away.

Technology-driven Operations

Our platform offers real-time access to inventory, shipment tracking, and documentation in one place. Empower your teams with full visibility for faster decision-making

Cost Efficiency

Our diverse supplier base and lean operations help us offer competitive pricing while maintaining product quality, regulatory support, and on-time delivery

Regulatory Compliance

We go the extra mile to ensure ingredients are sourced ethically and sustainably. Every product is supported by complete documentation that meets U.S. and global standards, including Kosher, Halal

Quality Commitment

We partner with trusted, globally audited manufacturers. Every product is backed by a Certificate of Analysis, Safety Data Sheet, and traceable supply chain for consistency and safety

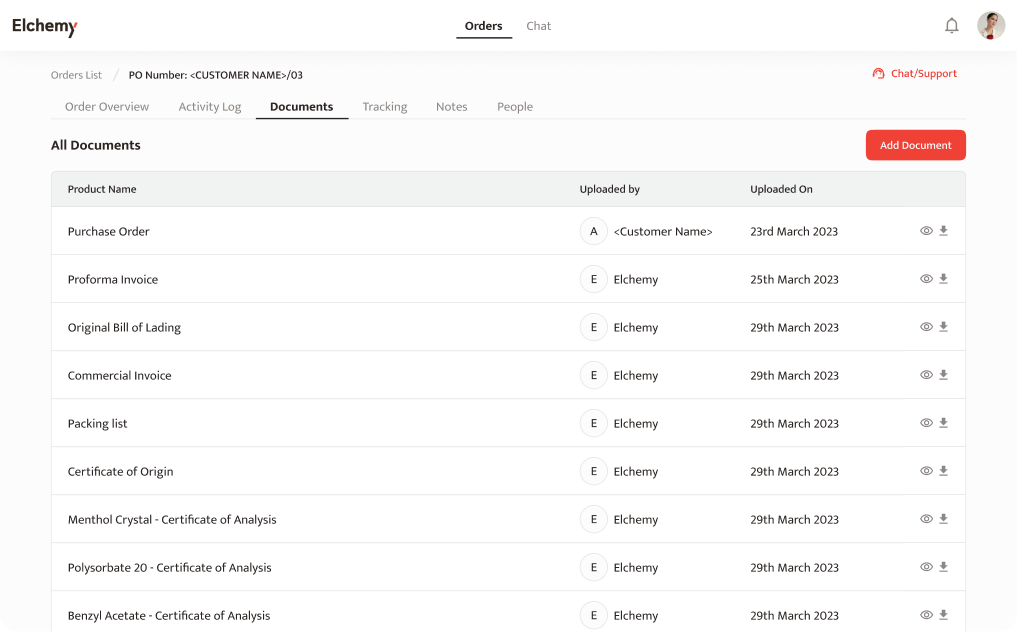

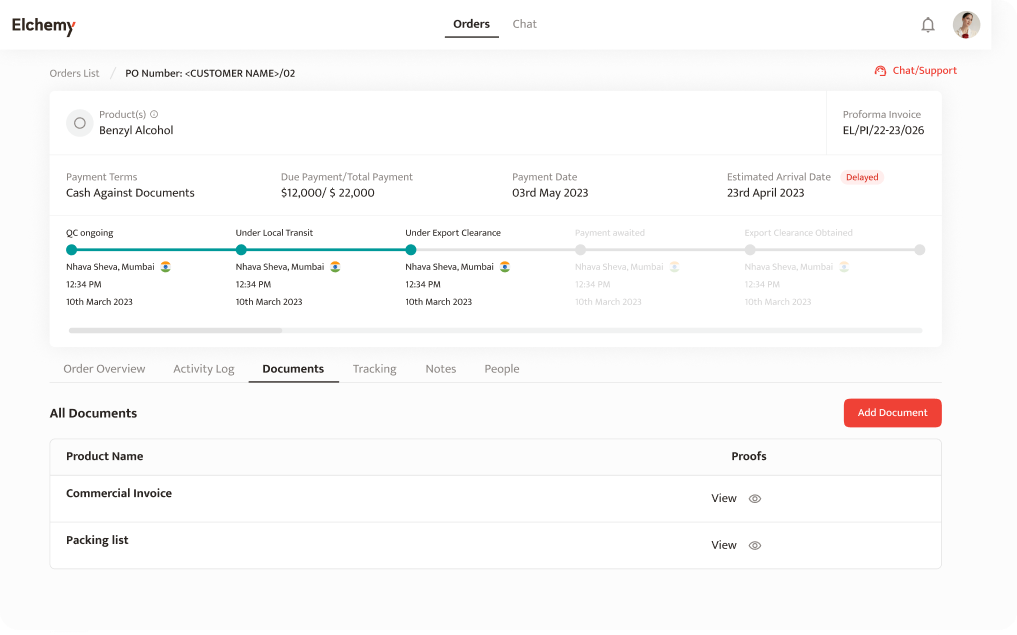

OUR TECHNOLOGY

Backed by Technology That Delivers Better Results

Our internal platform streamlines operations, improves communication, and gives your team faster, more reliable service from first request to final delivery.

Real-Time Shipment Tracking

Stay informed with order status updates and milestone alerts from dispatch to delivery, keeping you and your team in control

Real-Time Shipment Tracking

Stay informed with order status updates and milestone alerts from dispatch to delivery, keeping you and your team in control

Centralized Documentation

Access all regulatory and quality documents in one place — from CoAs and SDS to certifications and technical specs

Faster Turnaround Times

Our tech-enabled operations reduce manual steps and bottlenecks, enabling quicker response times and more dependable fulfillment

Compliance You Can Count On

Navigating chemical regulations across borders can be complex, but we make it simple. With a dedicated compliance team and documentation tailored for the US market, Elchemy ensures every product meets rigorous safety, quality, and regulatory standards.We help keep your operations audit-ready, well-documented and worry-free.

OSHA, FDA, and EPA aligned documentation

US based regulatory experts

Up-to-date CoAs, SDS, and import documentation

End-to-end traceability

Industry-Recognized

Credentials of Trust

ELCHEMY EXPERTISE

Custom Manufacturing

Elchemy makes custom manufacturing simple, scalable, and reliable. Whether you need support with development (CDMO), research (CRO), or production (CMO), our network of audited sites and technical experts helps you bring high-quality products to market faster

Achievements at

ElchemyAchievements at Elchemy

Industries

Countries

MT Shipped

Ports

RESOURCES

Blogs, Events & News at Elchemy

BLOG

EVENTS

BLOG

EVENTS

Streamline

your chemical

procurement

Get fast responses from real experts